1.4 Preventative Maintenance

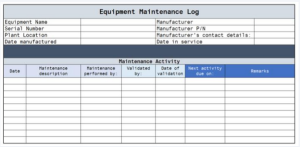

Poorly maintained equipment may become an ignition source. Be sure to keep a written log of the ongoing maintenance. There are several key components of a well implemented preventative maintenance program.

Inspection and Lubrication

Preventative maintenance includes regular scheduled inspection of….

- Grain Dryers

- Bucket Elevators

- Grain Stream Processing equipment

- Dust Collection and filters

Preventative maintenance also includes keeping a regular lubrication schedule. The specific schedule is based on…

- Manufacture recommendations

- Prior operating records

Certification Records

Preventative maintenance includes properly filled out and filed certification records. These records include the following pieces of information:

- Maintained for each inspection

- Date of the inspection

- Who performed the inspection

- Serial Number or other identifier of the equipment

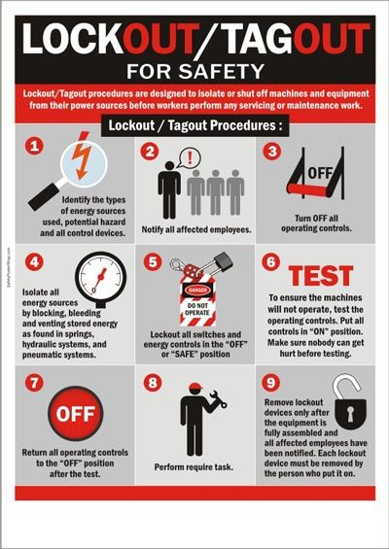

Lock Out Tag Out

Remember to isolate all sources of energy:

- Electrical

- Mechanical

- Hydraulic

- Pneumatic

- Stored

Click through each step below to learn more details of the Lockout/Tagout steps highlighted in the video.

This small poster depicts the nine Lockout / Tagout procedures described above. Clicking on it opens a larger image.

Hot Work

Hot work is any work that involves burning, welding, cutting, brazing, soldering, grinding, using fire- or spark-producing tools, or other work which produces a source of ignition. Welding and cutting operations are common to drilling and servicing operations. If possible, hot work is only conducted in safe designated areas.

If hot work must be done in areas outside of a safe designated area, a Hot Work Permit system must be used. This would include in areas where hazardous materials are stored and cannot be removed, or in areas where flammable atmospheres could exist.

Hot Work Permit requirements include:

- Area within 35 ft of the work must be cleaned of dust.

- Other combustibles within 35 ft must be moved, covered, or guarded.

- Combustible floors wetted or protected.

- Equipment cleaned of combustible materials.

- Combustible dust or flammable vapor producing equipment not permitted in the area.

It is important for the employer to have a hot work program

that covers hot work requirements, including permits.

Outside Contractors

In cases where outside contractors are hired for performing maintenance or repairs, employers must inform outside contractors about each of these:

- Potential fire and explosion hazards

- Safety rules of the facility

- Emergency Action Plan

Review

Work through these interactive questions to review the important concepts discussed.

Safety procedures used to ensure that machinery is properly shut off and cannot be started up again before maintenance or repair work is completed. This prevents accidental startup and injuries.